Ceramic Foam Products

|

Specification:

Typical Applications: In recent developments, pressureless sintered SiC ceramic foam products with porosity varing from 10 to 30 PPI have been successfully used as porous burners for (near) zero emission applications. Some typical examples are: internal combustion diesel engines, after-burner in SOFC (solid oxide fuel cell) systems, domestic boilers, etc. The growing usage of ceramic foam products in recent years stems from the favorable properties such as low density, low/high thermal conductivity, and from their excellent thermal and chemical stability.

Test results have shown that the use of ceramic foam structures as catalyst support can be beneficial in case of strongly exothermic or endothermic reactions. For these cases the thermal conductivity of the foam material is very important as it can allow for a rapid heat exchange which may accelerate the mass transfer. In addition, a thin layer of catalyst coated on foam (instead of catalyst pellet as in the case of packed bed configuration) and the macro porosity of the foam structure can improve the diffusion of reactants and products which may lead to a better performance of the catalyst. |

|

Foam Plate 1 150x150x15 mm |

Foam Plate 2 200x300x15 mm |

|

Foam Block 200x200x50 mm |

Foam Cylinder Ø200x200x20 mm |

|

Composite ceramic foam plate 10 PPI/40 PPI or Al2O3/SiC combination |

Tailor made ceramic foam special shapes

|

|

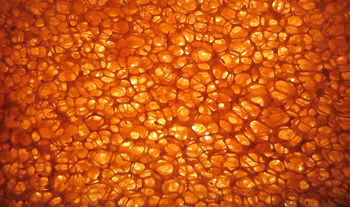

Ceramic Foam Lamp Shades |

SiC ceramic foam plate 10/20/30 PPI, 200x300x15 mm |

Foam ceramic burners

Product code: BSP C05A

|

Description: Al2O3 foam ceramic blocks and plates, porosity 10-60 PPI When used in ethanol burners, ceramic foam block helps holding up the ethanol fuel (therefore avoiding spilling), and at the same time facilitates a special attractive, even set of flames and simple operation down to the last drop. In case of gas burners, the ceramic foam plate helps to improve the gas combustion efficiencies, reduce combustion noises and pullutant emissions, while at the same time generate more attractive flames. When required, ceramic foam burners impregnated with Pt/Pd/Ce catalysts can also be supplied. Tests have shown that catalytic burners significantly improve the combustion efficiency and provide a much better flame pattern.

|

|

|

|

|

|

| Ceramic foam ethanol burner | Ceramic foam ethanol burner | Ceramic foam gas burner |

Flat ceramic foam burners with a high emissivity coating

Product code: BSP C05

Key properties:

Material: Cordierite or Mullite

Porosity: 10 - 80 PPI

Thickness: 10-40 mm

Size: max. 400x400 mm

Max. capacity: 2000 kw/m2

Turndown ratio: 20

Suitable for:

Natural gas, LPG, propane/butane, bio gas

Condensing boilers, infrared heaters/dryers, fireplaces, gas treatment post burners

Solar Energy Receiver / Heat Exchanger

Ceramic SiC foam plate in combination with a die-cast aluminium component to form an ideal

high performance solar energy volumetric receiver / heat exchanger

|

Cylindrical ceramic foam burners

Also possible: with a high emissivity ceramic coating or loaded with partial oxidization catalyst Application: condensing boilers, Stirling engines, CSP volumetric receivers, special gas burners |

|

|

|

|

|

1. Free flame burner for gas/ethanol fireplaces

|

|

|

2. Radiant gas burner for high efficiency and low NOx /CO emission boilers, ideal substitute for blue flame burners

3. SiC foam cylinders used as solar volumetric receivers and solar chemical reactors.

Catalytic Fireplace

| Catalytic fireplaces are wood burning units that contain a device similar to the catalytic converter in a car. These devices are known as catalytic combustors and are also commonly referred to as cats. These can come as fireplace inserts which are able to be installed into both pre-fabricated and masonry fireplaces.

Normally smoke will burn or oxidize, at a temperature of 540 °C (1,000 °F) or higher. Burning a stove this hot would require continuous intense fire and would require a higher wood consumption. The answer to eliminate this is the catalytic combustor. Wood smoke gases coming in contact with the catalyst, causes chemical changes to take place. This will then allow the smoke to ignite at temperatures around 260 °C (500 °F). This temperature is easily achieved in the firebox of a wood burning stove. As the wood gases ignite and burn within the catalytic combustor, clean by-products of water vapor (H20) and carbon dioxide (CO2) are emitted. A catalytic combustor is a foam or honey-comb shaped chamber made of ceramic materials. It is coated in a metal catalyst, such as palladium or platinum or a combination of both, which is then installed into the firebox near the base of the chimney or flue. The purpose of this device is to lower the combustion temperature of the smoke and gas emissions thereby causing them to burn up before they even leave the combustor. This, of course, means fewer emissions are released into the atmosphere. It also makes the catalytic fireplace a more fuel efficient unit because it produces more heat for less wood. Catalytic combustors are available in retrofit kits that enable consumers to convert non-catalytic wood burning units into a money saving, environmentally friendly catalytic fireplace. Performance of stoves equipped catalytic combustors: Thermal efficiency: > 85% CO emission: < 70 ppm Particulate emission: < 35 ppm Apart from wood burning fireplaces, catalytic combustor can also be used for flueless gas fireplaces. A recent development has shown a new generation of catalyst combustor using nano technology is able to "burn" CO at temperatures below 100 °C (210 °F). |

Filcat® -- A new development to combat fireplace emissions

|

Modern heating systems fired by solid fuels (especially firewood and pellets are designed to be efficient, safe, low-emission solutions that help to increase the comfort of building occupants. One of our major efforts in this area focuses on developing ways of reducing flue gas emissions, especially particulate matter. Filcat® is just one example of our recent developments. |

|

|

|

||

|

Filcat® unit |

Inside view |

||

|

|

|

||

|

Top view |

Ceramic foam plate loaded with catalyst |

|

Filcat® is in fact a combination of particulate filter, catalytic combustor and heat exchanger, specially developed for wood burning fireplaces. Filcat® can be used both for new fireplaces and for retrofit of existing ones. Consisting of a metal casing and 3 layers of ceramic foam plates (porosity between 20 and 60 PPI) loaded with high performance catalysts, Filcat® is able to reduce fireplace dust emission of more than 80% and CO emission below 70 ppm and at the same time to improve the fireplace’s thermal efficiency for at least 10%.

|

|

Type

|

Size, cm

|

Capacity, kW

|

|

Filcat® A

|

20x22x15

|

4-9

|

|

Filcat® B

|

35x22x15

|

8-16

|

|

Filcat® can also be up-scaled for wood pellet burning systems, bio mass combustion systems, wood gas CHP plants, wood chip heating systems, waste incineration plants and other industrial applications.

|