Coldlite® A New Type of 3D Printing Ceramic Material

|

The basic idea of 3D printing (or additive production) technology is not new. In fact it is rather simple. It is the computerized process in combination with internet technology that makes 3D printing interesting. 3D printers capable of outputting physical objects have been in development for over two decades and are starting to present a whole host of new digital manufacturing capabilities. Among the 3D printing enthusiasts and professionals the choice of an optimal printing material as well as the binding (and solidifying) technique has been considered as a major factor which determines the printing efficiency and the subsequent production cost. In recent years, 3D printing ceramic products are receiving more and more attention and finding more and more applications. At present, there are two types of raw materials commercially available for ceramic printing: i.e. clay (paste) printing and powder printing. As a new comer, we proudly introduce Coldlite™ into the 3D printing ceramics family. Coldlite™ is a proprietary product developed on the basis of more than 20 years knowledge and experience of ceramic materials. Composed of 100% inorganic components and supplied in a paste form, Coldlite™ hardens and hence solidifies into a ceramic material under ambient conditions. In other words, Coldlite™ is really a cold ceramics for which no firing (sintering) process is needed. Compared with other printing materials currently available, Coldlite™ is very price competitive and very easy to use. Coldlite™ tremendously simplifies the 3D printing process and considerably reduces the overall production costs. Coldlite™ is mostly suitable for the quick production of prototypes. Colors available: white, milk white, gray, brown, black.

Please contact us for more information. |

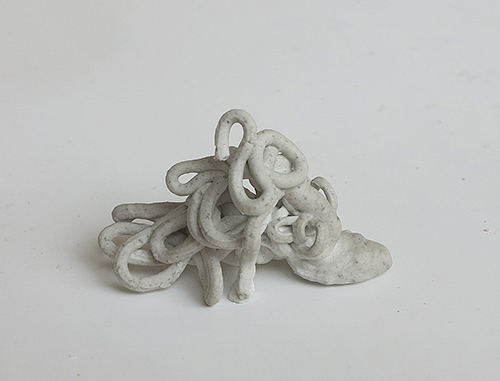

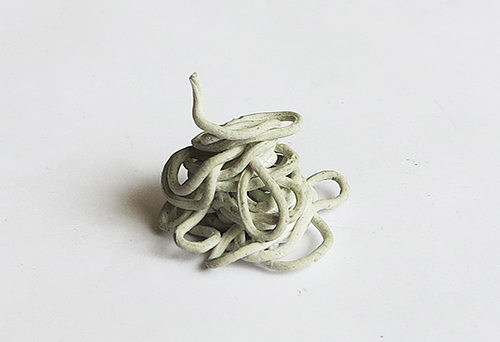

Examples of Coldlite™ printing products